|

What the heck is a cut-out raiser??

Updated Jan 23, 2001

*Turbo Gus Mahon,

unfortunately, is no longer with us. He was killed in late

Summer 2002 in a motorcycle accident. He was quite an inventive

person and was able to propel his 2.5L Turbocharged Dodge

Caravan into the 13's at the dragstrip, frustrating many

musclecar owners to no end. We will be reprinting some of his

more generic articles mainly due to the great information they

provide. We are extremely sorry to hear about the tragic

accident that took his life, but will remember always the

contributions he has made to the hobby. The following is the

article in full along with how the results were derived.

When you

are manually raising the boost on a Mopar turbo car (and many

other brands, too!) you quickly discover that at some point

above stock boost levels the engine will SHUT clean off (or "CUT

OUT"). It's very annoying, to say the least. In our beloved

Mopar FWd turbo cars cut out is most often at 14.7 psi. The

computer can't recognize boost levels above 14.7 psi, so it

shuts your motor off if you try to go higher.

We can fool the MAP sensor into telling the computer that

we're still below 14.7 psi. We can keep the pressure down in the

MAP sensor line with this device which raises the cut-out point,

or eliminates it (if you want to go that radical).

Making a

Cut-out Raiser

Because of

legalities, I can only suggest this as an off-the-road mod.

Attempt this at your own risk.

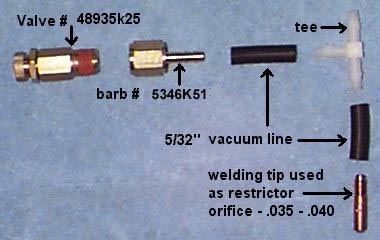

McMaster-Carr

sells the un-modified valve as part number: 48935K25

Modify as follows:

First take the stock valve, disassemble it by unscrewing it, and

re-assemble it with the steel ball moved to the OTHER side of

the spring. The steel ball will now be on the red-threaded end

of the valve.

Then get a screw-on barb (McMaster-Carr part# 5346K51) and screw

it onto the red-threaded end.

...and put

together a couple of short pieces of vacuum line, a tee, and a

restrictor orifice (brass piece with pinhole in it).

I pick up welding tips at a local welding store. That's one in

the picture above. Below is a completed valve.

WARNING!! The restrictor orifice (or welding tip) should be

.040" to .050" A small orifice, like some stock ones, will cause

the "check engine' light to come on. The illustration above

shows .035" as the smaller limit, but actually .040" to .050" is

better.

INSTALLING the cut out raiser

If you

have the old style logic-module-in-the-kick panel setup, then

you put this device in the car, or underhood.

In the car: splice into the vacuum line that goes to the MAP

sensor - logic module. Pull back the passenger's side footwell

carpeting, or remove the kick-panel. Splice in the cut out

raiser with the white nylon connector facing the MAP sensor. Of

course the brass restrictor points the other way!

Under the

hood: Splice into the vacuum line close to where the vacuum line

for the MAP goes through the firewall. Splice into the line near

the firewall with the white nipple facing the firewall, and the

brass nipple towards the barometric solenoid.

If

you have the newer style barometric solenoid/MAP sensor together

under the hood, think of the baro/MAP combo as one device. Cut

the vacuum line close to the baro/MAP sensor, and splice in the

cutout raiser device with the brass nipple towards the intake

manifold, and the white nylon nipple towards the MAP

sensor/barometric solenoid combination.

Minivan before:

Minivan after:

DIALING IN the installed unit

After

installation, screw the knurled knob almost all the way in, and

the car will still cut out around 15 psi. Loosen the lock-ring,

and unscrew the knurled brass knob a half-turn. Re-tighten the

lock-ring. After you do this a few times, you�ll notice that the

cutout point gets higher. You can stop at 16, or 18, or whatever

you want, BUT, the higher you go, the more fuel you have to add.

Set it as

low as you can get away with, because your computer will give

you NO MORE fuel past14.7 psi. The computer will believe that

you�re never going over 14.7 psi!

If you have a rich-lean gauge, back off when the gauge

indicates that you are NOT rich!

If you have no gauge, run a wire from your O2 sensor wire (the

one that reads .1V-.9V at warm idle, bouncing up and down)

through the firewall, into the car. Hook the O2 wire to the red

probe of a digital voltmeter; hook the black probe of the

digital voltmeter to a clean ground. When you floor it, you want

to see .87V to .97V. Less than .87V means you�re not safely

rich. Back off, and add fuel.

You can add fuel by raising the fuel pressure, adding an

extra injector, or switching to slightly larger injectors. If

you don�t add any fuel, don�t run high boost! I can usually run

15 psi on the stock setup.

FINISHED!

Here's a

simpler MAP bleed without the Grainger valve. You need a needle

valve, and a restrictor orifice instead.

The Grainger valve set up will leave you at full richness

until you hit14 psi or so. Then you'll begin to lean out.

This needle valve set up will lean you slightly all the

way through your boost curve. If you're running too rich from

big injectors, this needle valve set up is better for you. If

you want to raise the boost just2 or 3 psi past cut out, this

will be good for you, too.

NEITHER set up will affect idle, gas mileage, or part

throttle cruise. They only come into play when you go into

boost.

Do NOT

open the valve much to start with. Just open it enough to bring

your cut out point a little higher. The brass needle valve can

be replaced with another simple restrictor orifice. The smaller

the orifice, the less raising of the cut out point; the larger

the orifice, the more raising of the cut out point.

If you are running computer controlled boost, this needle

valve mod will *also*raise your boost level!

I designed this set up for manually boosted cars.

Computer controlled cars will see a rise in their boost. Will

make a fun experiment. Just go easy on the throttle 'til you see

where your new boost level is. If you don't bleed much, the

boost won't go up much. And you *don't* want to bleed much...

|