|

This

set of pictures shows how I made the shifter cable set up. I

took the TH-125 shift arm and installed it on the 4T60E but did

not like the angle of the arm when installed, so I ended up

using the 4T60E arm but turned 180 degrees from the stock donor

car position. The stock TH125 Fiero shifter arm is 1 5/8" from

the center of the stud to the ball link. On the 4T60E, when I

went through the gear detents and at this distance the ball

moved 3/8" between the gears. This distance is shown by the

small hole I drilled in the shift arm. When I checked the

distance the shift cable moved between gears with the shifter,

the cable moved 1/4". I then checked the shift detents on the

TH125 tranny and the ball also moved 1/4" between gears. I had

to find where to put the ball on the 4T60E arm to get the 1/4"

ball movement between gears. This distance ended up being 1 3/8"

from the stud center to the ball.

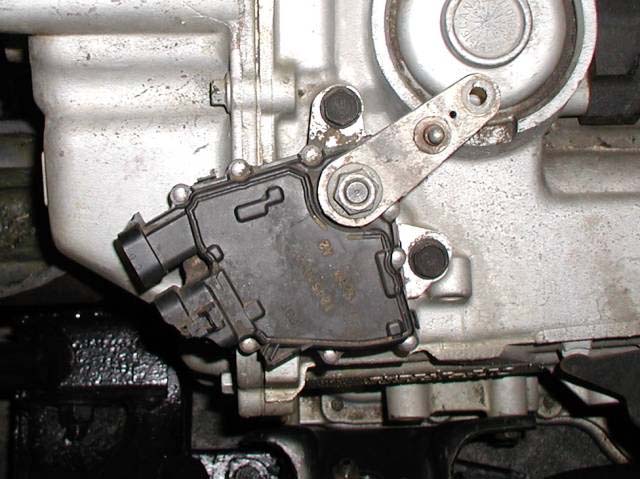

I wanted the bracket to be at a 90 degree angle to the arm in

neutral gear. I ended up using part of the TH125 and part of the

4T60E bracket welded together to make my new bracket. In the

picture, the part bolted to the tranny is the 4T60E piece, and

the part where the cable goes through is the TH125 Fiero piece .

This is a picture of what the completed setup looks like, put

the shifter arm into the neutral position ( 2 clicks to the

right from the left position). set the shifter in the neutral

position, then adjust the cable length so the eyelet fits on the

shift lever ball. with this setting the shifter gear detent

locks will be in the right position for neutral and reverse and

the shifter will downshift all the way down to 1st gear.

When

I got to the problem with the axles, I saw that people had been

using different combinations, but I noticed it was mentioned

that the passenger side axle was different for the 4t60e

compared to the 4t60. I found that a few people were saying that

axles on both sides of a 94 Beretta w/v6 would be a direct fit

for my transmission so I went to a Car Quest parts store and bought a

set of rebuilt Beretta axles. The axles will probably come with

an abs locator gear. This can be removed with a hammer and

chisel. When I installed the axles I ran into some problems. The

driver's side was a good fit, but when I installed the passenger

side both ends of the axle assembly were correct but the axel

itself was too short. The tripod bearing actually pulled out of

the housing when I tried to install the axle nut. After a little

investigation it appears the passenger side was about 2" too

short. (see picture)

The

first thing that I looked at was the boots. The small end fits

into a groove in the axle, so you can roughly tell how long the

axle is by measuring the distance between the boots. On the

Beretta passenger side axle it was 1.5", so if I add 2" to that

length, I am looking for a axle with about a distance of 3.5".

Now I don't have the resources to go through rebuilt axles to

find the one I need. So what I ended up doing was I still had

the axles from the Monte Carlo donor car and there was a

distance of 3" on the driver's side and 4.5" on the passenger

side between the boots, and the axles had the same diameter of

axle shafts as the Beretta's. I decided the axle with the 3"

distance might work so I disassembled it to remove the shaft.

Now when I disassembled the Beretta shaft I compared it's length

to the Monte's and the Monte's was exactly 2" longer. This

turned out to be just what I needed, so I put the ends of the

Beretta axle assembly onto the Monte Carlo axle shaft, then this

was a perfect fit into the Fiero.

Author:

Mike Kaas |